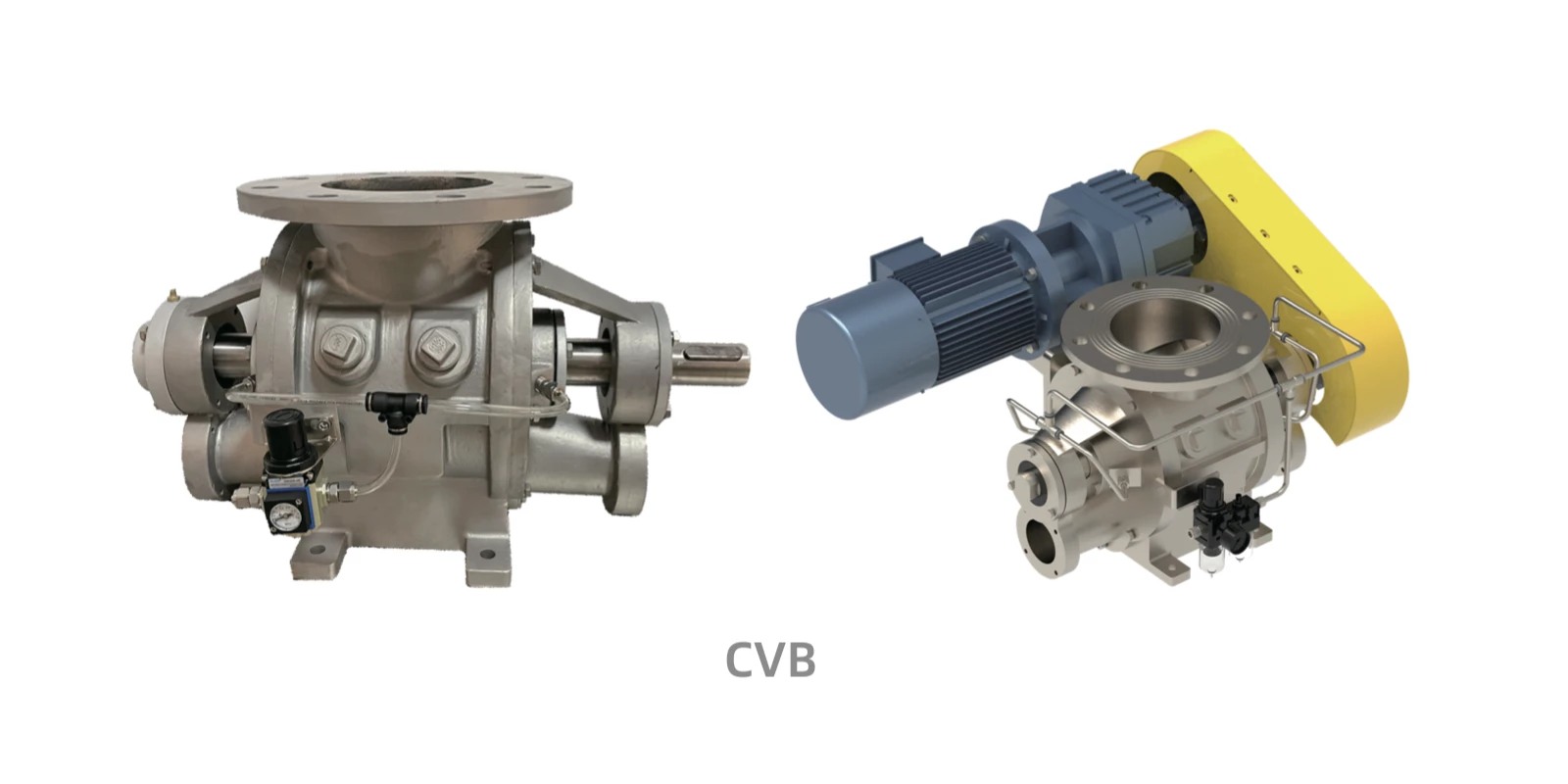

Blow Through Rotary Valve For Powders

Description

- For direct connection in pneumatic conveying pipelines.

- For feeding bulk materials into pneumatic conveying systems.

- Up to 1.5 barg (21PSI).

- Handling free-flow powders in food, grain, chemical, plastics, pharmaceutical applications.

- Enable to operate without leakage gas venting.

Features

- Standard valve manufactured in stainless steel, cast iron

- Nonstandard valve manufactured in Hastelloy, Nickel Alloy, Titanium material

- ANS1 150#, DIN PN10, JIS1OK Drilled flanges in accordance with DIN, ANSI, JIS standard

- Outboard bearing are standard

- High temperature execution up to 300°C

- Pressure difference up to 1.5bar (21PSI)

- Open ended rotor with 8 vans

Option And Accessories

- 6 vanes, 8 vanes, 10 vanes or 12 vanes rotor

- Rotor design: open end, radius pocket and adjustable-tip

- Interior coating: tungsten, Teflon, ceramic powder, hard chrome

- Air purge shaft sealing

- Valve housing leakage gas venting

- Accessories: Drop-out box, speed monitor, vent box