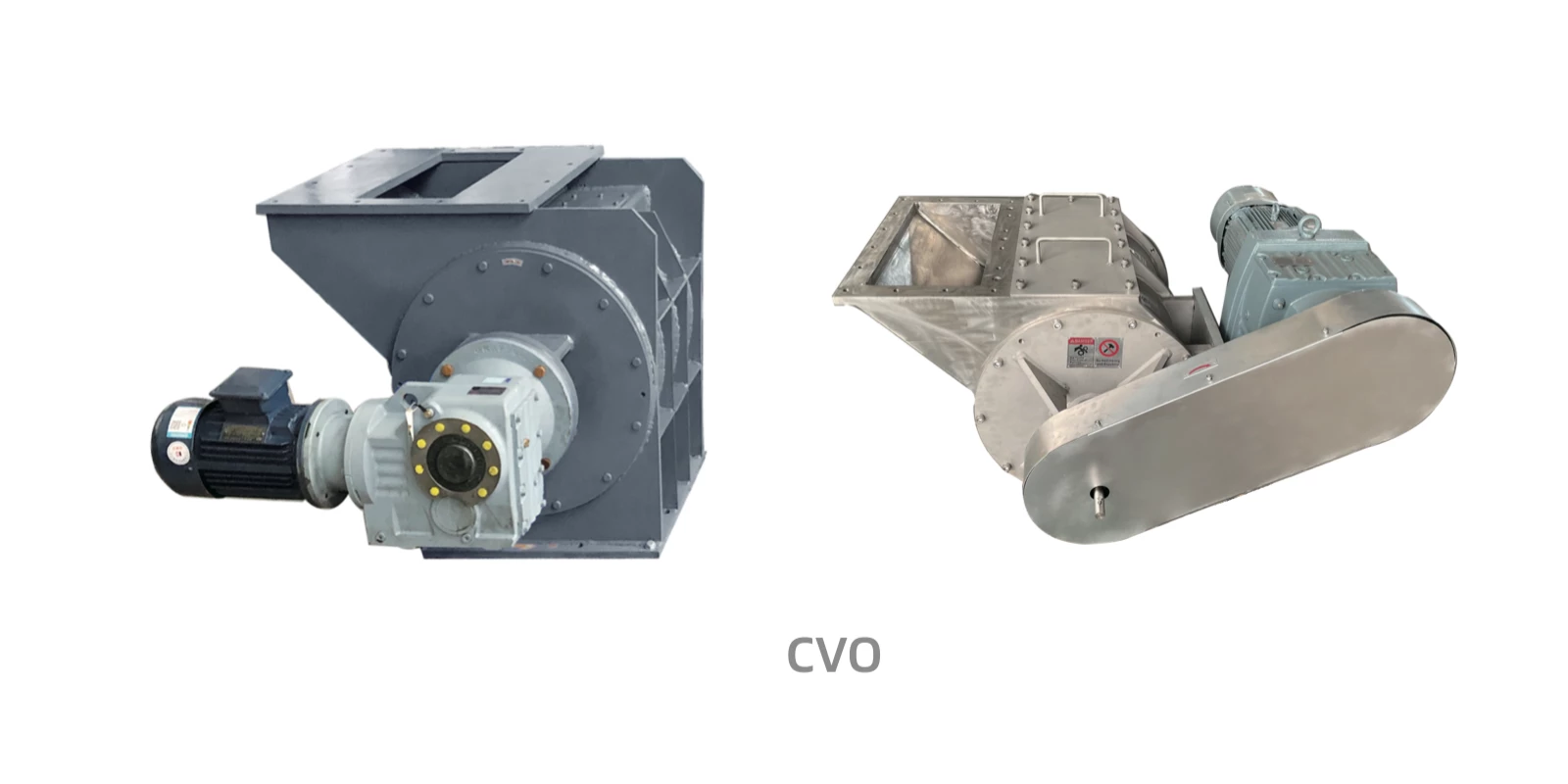

Discharging Rotary Valve For Granules

Description

- Worked in applications where product shearing is a concern .

- The processing material enters the side of the rotor instead of the top.

- The product is caught on the upswing of the rotor blades so that the product is constantly falling away from the shear point.

- The rotor pockets also do not fill up as completely, additionally reducing the likelihood of shearing.

Features

- Standard valve manufactured in Stainless steel, Cast Iron, wear-resistant material like

hardox500 - ANSI 150#,DIN PN10, JIS I OK Drilled flanges in accordance with DIN, ANSI, JIS standard

- Heavy shaft diameters minimising deflection

- Maximising valve speed to 25 RPM prolonging life, ensuring good throughput

- Pressure difference up to 1.5 bar (21 PSI)

- Closed ended rotor with 6 vans

Option And Accessories

- 6 vanes, 8 vanes, 10 vanes or 12 vanes rotor

- Rotor design: close end, helical rotor, V-type rotor, radius pocket and adjustable-tip

- Interior coatings: tungsten, Teflon, ceramic powder, hard chrome

- Packing gland sealing or Air purge shaft sealing

- Accessories: Drop-out box, speed monitor, vent box