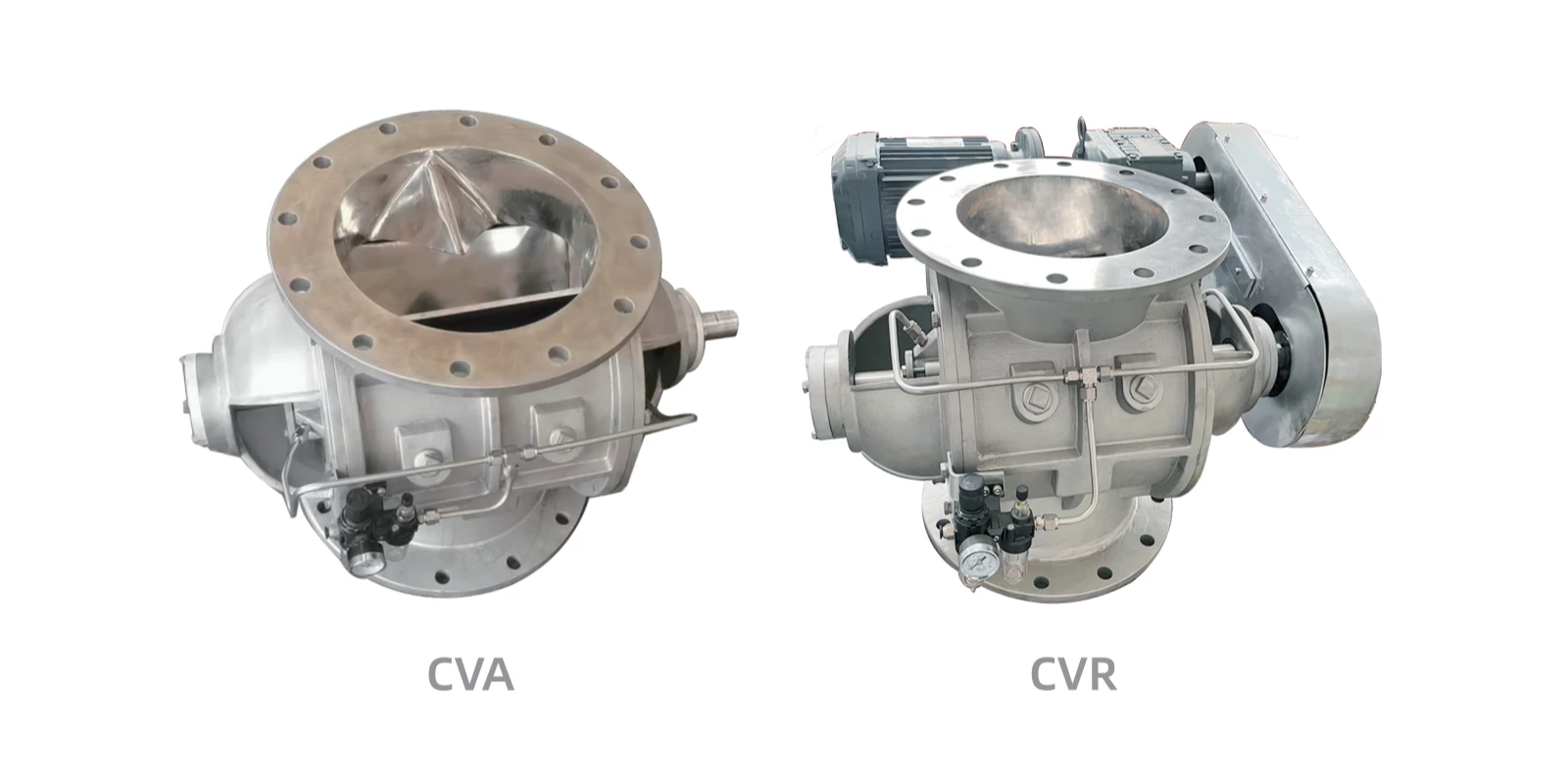

Discharing And Metering Valve For Powders And Granules

Description

High duties for high capacities, without restriction of the cross section for highest capacities. Pneumatic conveying systems for both metering and airlock duties, suitable for both vacuum and pressure applications. Processing powders and granules. It can operate without leakage gas venting.

Features

- Standard valve manufactured in stainless steel, cast iron

- Nonstandards valve manufactured in Hastelloy, Nickel Alloy, Titanium material

- Drilled flanges in accordance with DIN, ANSI, JIS standard

- Outboard bearing are standard

- High temperature execution up to 300°C

- 1.5 barg (21PSI) system and differential pressure

- Open ended rotor with 8 vans

Option And Accessories

- 6 vanes, 8 vanes, 10 vanes or 12 vanes rotor

- Rotor design: open end, close end, radius pocket and adjustable-tip

- Interior coating: tungsten, Teflon, ceramic powder, hard-chrome

- Air purge shaft sealing

- Valve housing leakage gas venting

- Accessories: Drop-out box, speed monitor, vent box